Gigacasting provides fast and cheap production but is expensive to repair

Tesla, with its successes and its mistakes, has meant a paradigm shift in the automobile industry, not only by contributing significantly to the popularization of the electric car worldwide but also by introducing important changes in both the business model and the manufacturing process of their automobiles.

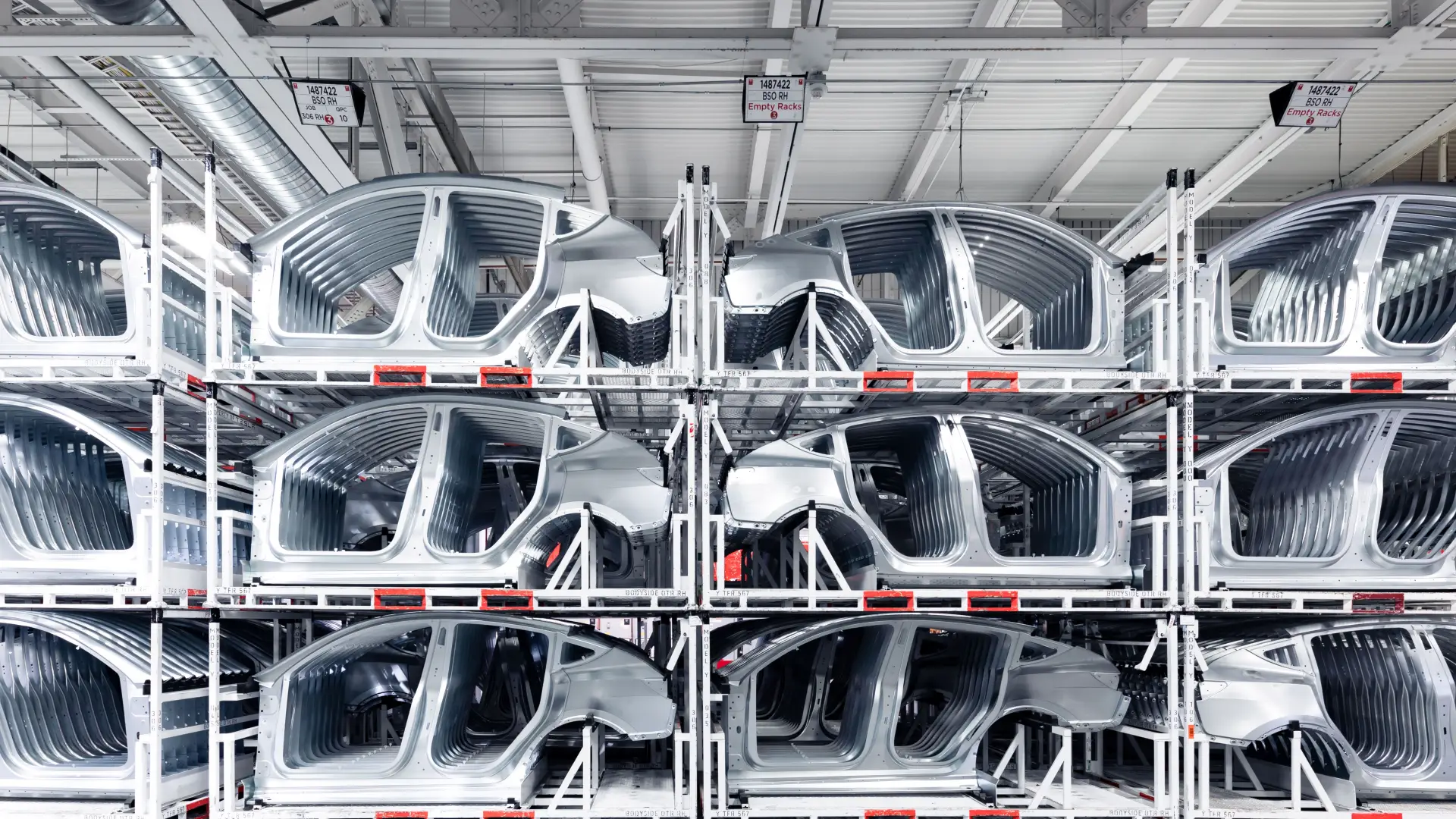

One of the company’s most notable innovations in this last field is “gig casting”, a procedure that allows the creation of large cast structures to reduce the number of body parts, which makes production cheaper and faster (until now, the car frame was made from numerous pieces of stamped steel welded together).

Aware of the enormous advantages of “gigacasting”, more and more groups are betting on this solution: Geely (Volvo, Zeekr…), NIO, Volkswagen, XPeng… Toyota recently confirmed that its next electric platform will be made up of only three modules (front, center, and rear frame), a revolution “at the height of the monocoque chassis.”

The Japanese firm estimates that this new architecture will reduce manufacturing times by half. Renault pointed out a few days ago that, while a conventional car is made up of 2,400 parts, its next generation of electric cars will have just 700, which will help achieve a 40% cost reduction.

Insurance prices could also increase

However, some experts warn that mass adoption of this method will have negative consequences for consumers. The FEDA (French Automotive Distribution Federation) has echoed a study in which it is stated that the cost of repairing a rear impact in a Peugeot 2008 would go from 12,154 euros (with 6.5 days of work) to 15,402 euros (with 11 days of work).

Having to replace an entire block instead of the affected parts could even make the dent irreparable since the cost of fixing it would be greater than the value of the car itself. For this reason, insurance on vehicles assembled using this method could end up being more expensive.

“Gigacasting, synonymous with better margins for manufacturers, must not have negative consequences for the environment or consumers’ budgets, “ explains the FEDA, which asks the French government to “supervise this manufacturing process as soon as possible, for legislative or regulatory means, to prevent the generalization of mega-parts and the arrival of the disposable automobile.

The post Gigacasting provides fast and cheap production but is expensive to repair appeared first on Latest Car News.

Latest Car News

Comments

Post a Comment